Construction sites are rife with safety hazards, even if you take the greatest precautions. Among these hazards are electrical risks, which is also one of OSHA’s fatal four.

While most electricians, electrical subcontractors, and electrical engineers may be aware of the necessary precautions to avoid electrical injuries, they are not the only ones on these job sites. That’s why it’s important to follow electrical safety tips to keep contractors and workers safe.

It is the employer’s responsibility to provide a safe working environment and, when hiring subcontractors, it is important to determine their level of understanding of and commitment to electrical safety rules and practices.

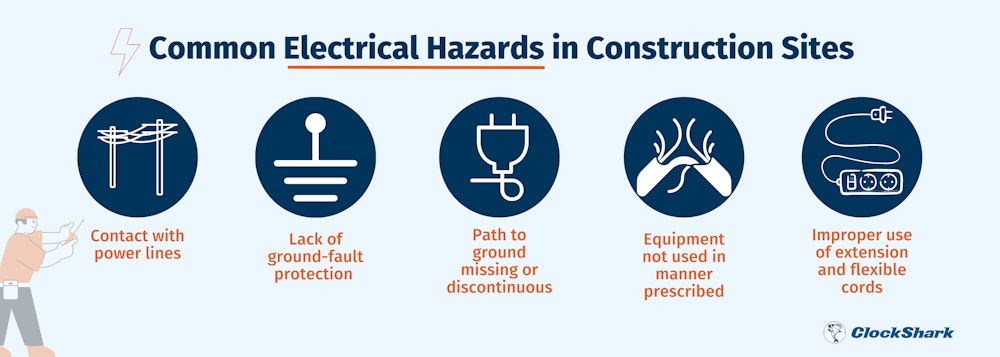

Common Electrical Hazards in Construction Sites

According to OSHA, hundreds of workers are injured or killed every year due to exposure to hazardous electrical energy. Further, they report the most frequent causes of electrical injuries on construction sites are:

- Contact with power lines

- Lack of ground-fault protection

- Path to ground missing or discontinuous

- Equipment not used in manner prescribed

- Improper use of extension and flexible cords

While these are the most frequent, they are not the only electrical safety hazards on the jobsite. Let’s dig deeper.

Improper Grounding

Grounding - also called earthing - is an important safety measure that prevents electrical shock by discharging excess electricity. If there is no grounding present, powerful electricity can build up in wires, cords, or connected devices (such as tools), causing injury.

Exposed Electrical Parts

Exposed electrical parts like wires or open panel boxes can cause serious injury, particularly for workers who are not trained in electrical safety.

Inadequate Wiring

Using extension cords or wiring that is not a heavy enough gauge can cause wires and cords to overheat, creating a risk of fire.

Damaged Insulation

All electrical cords and wires come with insulation to prevent exposed wires. Damaged insulation can cause a short, which can lead to arcing or cause a fire.

Overloaded Circuits

Overloaded circuits are the cause of many residential fires in the U.S. every year. An overloaded circuit is caused when too much electricity is connected to a circuit, so electrical current cannot adequately flow.

Damaged Tools & Equipment

Using damaged or broken electrical tools and equipment is a serious safety hazard. Not only can damaged/broken electrical tools result in incorrect or subpar electrical work, but injury as well.

Wet Conditions

Water and wet conditions are electrical hazards because water significantly increases the risk of electrocution and electrical shock.

Overhead Power Lines

Overhead power lines cause 40 percent of all electrical fatalities on the worksite, according to the Electrical Safety Foundation International. Jobsites with overhead power lines nearby, pose an electrical hazard.

Top Electrical Safety Tips

While electrical work is among the most dangerous jobs performed on construction sites, proper electrical safety measures and training can mitigate the risks associated with electrical hazards.

1. Conduct A Risk Assessment

Risk assessments are generally performed on all construction sites. However, electrical hazards may not be as readily identified by someone who is not properly trained in electricity. Be sure the person who performs the risk assessment is qualified and properly trained.

2. Use Cable Covers and Cord Protectors

Of course, electric work involves wires and cords which are often seen throughout a jobsite. Cable covers and cord protectors help protect wires from being damaged, and keeping cords organized and out of the way, prevents workers from tripping over them.

3. Use Voltage Regulators and Circuit Breakers

Voltage regulators serve to protect equipment from electrical surges and surge protectors and/or circuit breakers serve to shut things down in the event of an emergency.

4. Use Personal Protective Equipment (PPE)

PPE is required by law for all workers on a jobsite. However, for electrical workers, additional PPE requirements apply. Be sure your electrical workers or subcontractors have - and are using - the proper PPE that is in proper condition.

5. Use High-Quality Testing Equipment

As with any tool, better-quality electrical equipment will yield better results and likely have a higher safety rating. Inferior electrical tools or testing equipment may result in subpar work and/or inaccurate information. Compromised or damaged electrical equipment and tools should be avoided or - if repaired - should be repaired only by a qualified and properly trained person.

6. Ensure All the Crew Have Proper Training in Electrical Safety

One of the greatest risks posed by electrical hazards on the worksite is having workers who are unaware of electrical safety rules and risks. Be sure your entire crew has a clear understanding of electrical safety.

7. Avoid Working in Wet or Damp Conditions

As mentioned above, water dramatically increases the risk of electrocution. That’s why electrical work should be avoided in wet or damp conditions to reduce the risk of injury.

8. Be Wary of Improper Grounding

Improper grounding causes health and injury risks. If you or your workers are experiencing electrical shocks when touching metal objects or using tools, it is likely a grounding problem that should be immediately addressed.

9. Install Physical Barriers Around Electrical Hazards

Having clear and easily understood barriers and notices around electrical hazards will help reduce the risk of workers being exposed to injuries from shock, or worse. When working near overhead power lines, be sure workers are aware of the risks associated with contact with these lines, and understand the importance of always looking up - in all directions - when working near them.

10. Perform Everyday Audits

Ideally, as your project continues, changes will occur daily. That’s why it’s important to do a walkthrough of your jobsite and verify the correct and required electrical safety protocols are being followed and/or determine if any new electrical hazards have developed, so they can be addressed.

11. Continue Safety Training

Safety on the jobsite continues to be the most important part of working in the construction industry. Regular safety meetings are a crucial part of instilling a workplace culture of safety, and ensuring your crews understand the importance and necessity of proper workplace safety practices.

Electrical Safety Is Important in Construction

Electrical work is among some of the most dangerous performed on jobsites for many reasons. Not only does it involve working with live current, but many workers are not familiar with the hazards that exist when it comes to electrical work. However, following these electrical safety tips will help reduce the risk of harm or injury due to electrical problems and your crew should be a part of establishing a jobsite that is safe from electrical hazards.